AB Torkapparater is a family-owned business established and run in the Bojner family for 3 generations. Founded in 1937 by my grandfather Gustav Bojner, my father Gösta Bojner took over during the 1960's and today Torkapparater is run and owned by me, Ulf Bojner.

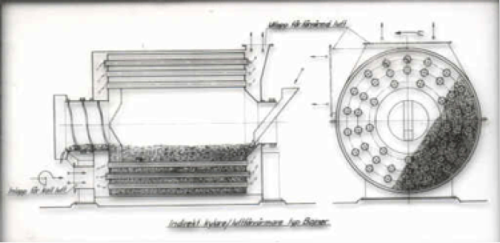

My grandfather Gustav Bojner left his position as Head of the drying department of KMW and Svenska Fläktfabriken in order for him to develop his own ideas fully. Gustav was the engineer who had his head full of ideas. He was widely known for his innovation capacity and he was rewarded several awards and he held over 40 patents in his portfolio. The most important patent was granted in 1947 and described a rotating head exchanger for free flowing materials. It soon became world news and even today the rotary heat exchanger – Tubulären - remains the Torkapparater main speciality.

Patent sketch from 1947

The foundation and the mission statement of the company has remained the same throughout its history. Torkapparater develops, manufactures and sells industrial thermal processing equipment with unique solutions for a wide range of materials. Standardized equipment has never been our business!

Our Business Idea

AB Torkapparater supplies complete systems for thermal treatment (drying, cooling, pyrolysis, gasification) of solid materials. Our systems are well-known for its quality and design features that give our clients correctly adapted equipment and sustainable system solutions at competitive total cost of ownership and lifecycle management.

Clients with numerous applications

Our first clients came from the chemical and mining industry. During WW2 energy supply became a critical issue and Torkapparater supplied plants for drying of forest by-products i.e., wood-chips, sawdust and peat. These are applications that again today are driven by the need for renewable energy, heat recovery and waste management.

Early Export growing into a global market

Today we have supplied over 1,200 plants worldwide, most of which are custom-made to our client’s specific needs. In the beginning we exported to the Nordic and Baltic countries, later also to Asia, Australia and the Americas. Torkapparaters technology has been manufactured under licence to suppliers in Japan and in the US.

Apart from dryers we also work with rotary kills e.g., calciners for mineral processing, and also limekilns for the pulp and paper industry. In 1968 we supplied a rotary kiln on to supports to India that was (and maybe still is) the longest of its kind (63,5 meter).

Complete solutions for heat treatment of solid materials

The demand for advanced system solutions has guided our product development. Torkapparater supplies complete system for heat treatment of solid materials. Including all supporting techniques in such a system. The core technology is our own, consisting of a rotary drum for direct or indirect heat transmissions, our systems are supplied with energy supply with heat recovery as well as materials handling and process automation. Each system is designed according to our clients’ regulations and high quality and environmental requirements and demands.

Torkapparater’s technology has been expanded with steam dryers and dryers for low temperatures as well as torrifaction reactors that meet the demand from the market to handle new materials.

What can I do for you?

Do you need assistant with thermal treatment and or process equipment?

We have experience from over 100s of different materials. We offer our clients to test their material in our mobile test plants.

Please do not hesitate to contact me or my colleagues for your inquiry

/Ulf B